Never miss an update from Universidad de Alicante

Create your free account to connect with Universidad de Alicante and thousands of other innovative organizations and professionals worldwide

The Institute of Organic Synthesis of the University of Alicante has developed a compound that allows the selective extraction of internal transition metals (lanthanides and actinides), avoiding the appearance of dangerous radioactive species.

TECHNICAL DESCRIPTION

In order to solve the problems described above, a TSIL (Task Specific Ionic Liquids) + IL (Ionic Liquid) extractant system has been developed that allows the selective liquid-liquid extraction of thorium from other metals belonging to the f, d and/or p blocks of the periodic table, such as uranium, without the appearance of dangerous radioactive species.

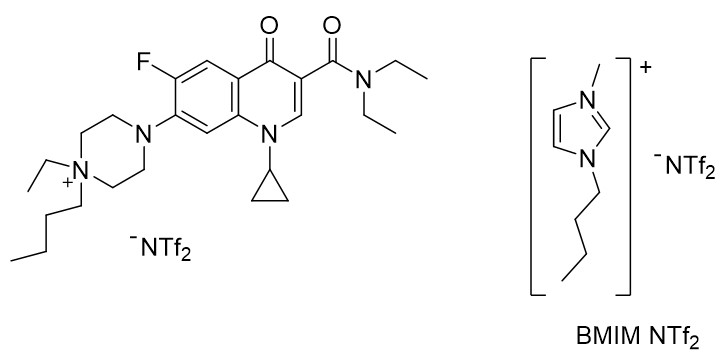

The invention is based on the preparation of an extractant mixture consisting of the compound TSIL dissolved in the ionic liquid BMIM NTf2 (see Figure 1):

Figure 1: Chemical formula of the compounds making up the extractant mixture.

The procedure for the preparation of the TSIL compound is carried out in three simple steps (under mild reaction conditions):

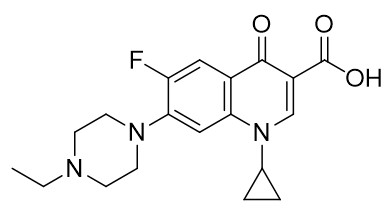

1. N-alkylation reaction of the antibiotic ciprofloxacin with 1-bromoethane to obtain the following intermediate compound (see Figure 2):

Figure 2.

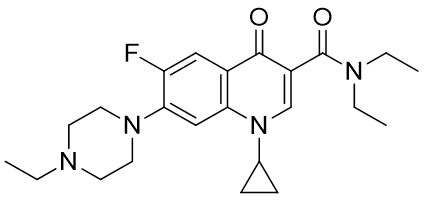

2. Amidation reaction on the previous compound using N,N-diethylamine to obtain the following compound (see Figure 3):

Figure 3.

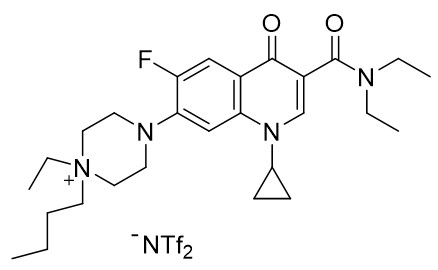

3. Alkylation reaction of the above compound with 1-iodobutane to give the compound TSIL with the following chemical formula (see Figure 4):

Figure 4.

The above chemical reactions are carried out in the presence of different catalysts under specific temperature and pressure conditions. Once the TSIL compound is obtained, it is mixed with the ionic liquid BMIM NTf2 to form the extractant composition (see Figure 1).

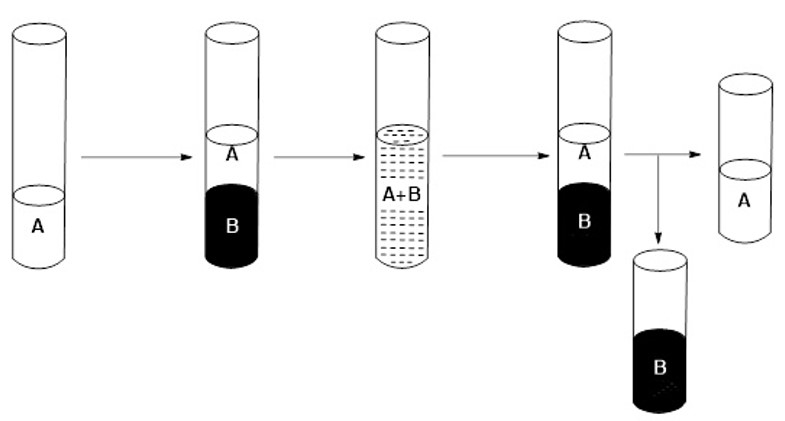

The procedure for the selective extraction of thorium from a sample containing thorium and other f-block, d-block and/or p-block metals of the periodic table is summarised in the following steps:

1) Prepare from the extractant mixture from the compound TSIL + the ionic liquid BMIM NTf2 (B).

2) Adjust the sample to be separated (containing thorium and other f-block, d-block and/or p-block metals) to pH=1 (A).

3) Add the liquid extractant mixture (B) to the liquid sample to be separated (A).

4) Shake.

5) Wait for the two solutions to separate by density difference.

6) Separate the two phases: the organic phase (B) corresponds to the extractant composition which includes the thorium initially contained in the sample to be separated (see Figure 5).

Figure 5: Selective extraction process.

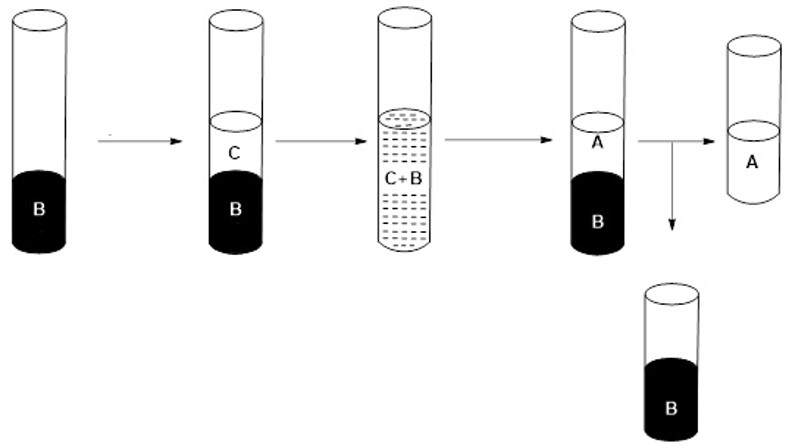

7) Add to the organic phase recovered in the previous step (B) an aqueous solution buffered to pH=6 (C).

8) Shake.

9) Wait for the two solutions to separate by density difference.

10) Separate the two phases: the organic phase corresponds to the extractant composition (B), which can be used again in other thorium recovery processes, and the aqueous phase (A) contains the extracted thorium (see Figure 6).

Figure 6: Schematic of the recovery process.

TECHNOLOGY ADVANTAGES AND INNOVATIVE ASPECTS

ADVANTAGES OF THE TECHNOLOGY

TSIL technology has the following advantages:

1) It allows the selective extraction of thorium against other metals belonging to the f, d and/or p blocks of the periodic table, such as uranium.

2) It is highly efficient in the selective extraction of thorium, allowing the thorium to be recovered in its entirety with a high yield due to its high affinity.

3) High specificity in the extraction of thorium from uranium and other internal transition metals (lanthanides and actinides): the rest of the metals are extracted with a low or null percentage.

4) It is possible to recover at least 95% of the extractant mixture and reuse it in further extraction cycles of thorium versus other metals.

5) The process is environmentally friendly, as it avoids the appearance of dangerous radioactive species such as plutonium, thus improving safety in nuclear processes.

6) The process is carried out under mild reaction conditions (temperature between 0ºC-25ºC and atmospheric pressure).

7) The process is feasible on an industrial scale and can be adapted and implemented to the needs of the company (the TSIL compound has a synthesis yield of 89%).

In summary, the TSIL compound is a revolutionary technology that significantly improves current thorium extraction methods by being safer, more efficient and selective. Its application in different sectors can have a positive impact on the environment and improve energy sustainability worldwide.

INNOVATIVE ASPECTS OF THE TECHNOLOGY

The TSIL technology has several innovative aspects that differentiate it from other similar technologies on the market.

Firstly, the novel chemical composition of the extractant mixture allows the selective extraction of thorium from other metals of the f-, d- and/or p-blocks of the periodic table, avoiding the occurrence of dangerous radioactive species such as plutonium.

Moreover, its high efficiency allows the thorium to be recovered in its entirety with a high yield, and it is possible to reuse the extracting mixture in new extraction cycles, making it a sustainable and environmentally friendly procedure (there is no other extraction system of these characteristics on the market that is recyclable).

CURRENT STATE OF DEVELOPMENT

The described technology has been developed at laboratory scale (Technological Readiness Level: TRL = 4).

The tests carried out have shown very promising results: the distribution coefficient (K), which is the ratio between the concentration of the metal in the organic phase and in the aqueous phase after extraction, calculated for thorium, is 28 times higher than that of uranium, and between 25-196 times higher for the rest of the elements studied (Lu, Yb, Gd, Sm, Nd, La, Y, Ce, Eu, Sc, Pt, Sb, etc.).

These tests have demonstrated the high efficiency of the TSIL compound in the selective extraction of thorium from other metals, as well as its capacity to recover the complexed metal in its entirety.

The results obtained indicate that this technology has great potential for application in nuclear processes. Furthermore, studies on the economic feasibility of the selective thorium extraction process with TSIL have been carried out, indicating that this technology could be cost-effective and competitive compared to other existing solutions.

COLLABORATION SOUGHT

Companies interested in acquiring this technology for commercial exploitation through patent licensingagreements are sought.

Company profile sought:

• Nuclear industry.

• Chemical industry.

• Nuclear medicine.

• Nuclear waste treatment.

TECHNICAL IMAGES (1)

Ahead of the current Coronavirus outbreak, Innoget is fully committed to contributing to mobilizing scientific and expert communities to find a real solution to the Covid-19 pandemic. Therefore, we're supporting worldwide calls and programs that could help in any aspects of the coronavirus crisis.

Is your organization promoting or looking for innovation or research initiatives to mitigate the Covid-19 outbreak? Email us at covid19@innoget.com to list them.

Channeled through Innoget's online open innovation network, initiatives in the health, virology, medicine, or novel technologies applied to human health, among others, are listed and disseminated to Innoget members -ranging from hospitals, research institutes, scientists, businesses, and public administrations- and innovation partners worldwide.

Create your free account to connect with Universidad de Alicante and thousands of other innovative organizations and professionals worldwide

Send a request for information

to Universidad de Alicante

Technology Offers on Agri-Food are directly posted

and managed by its members as well as evaluation of requests for information. Agri-Food is the trusted open innovation and science network aimed at directly connect industry needs with professionals online.

Need help requesting additional information or have questions regarding this Technology Offer?

Contact Agri-Food support